Address

LongGang Zhejiang China

Work Hours

Monday to Friday: 8AM - 5PM

Weekend: 10AM - 5PM

Address

LongGang Zhejiang China

Work Hours

Monday to Friday: 8AM - 5PM

Weekend: 10AM - 5PM

In the vibrant world of printing, various technologies have risen to the fore. Among these, the flexo printing machine holds a distinctive position. But, what is a flexo printing machine, and why is it integral to the printing industry? This article provides an insightful look into the workings of flexo printing and its versatile applications.

Flexography, often shortened to flexo, is a method of direct rotary printing that uses flexible relief plates. The flexo printing machine is the workhorse that makes this process possible, offering high-speed operations that can print on a wide variety of substrates.

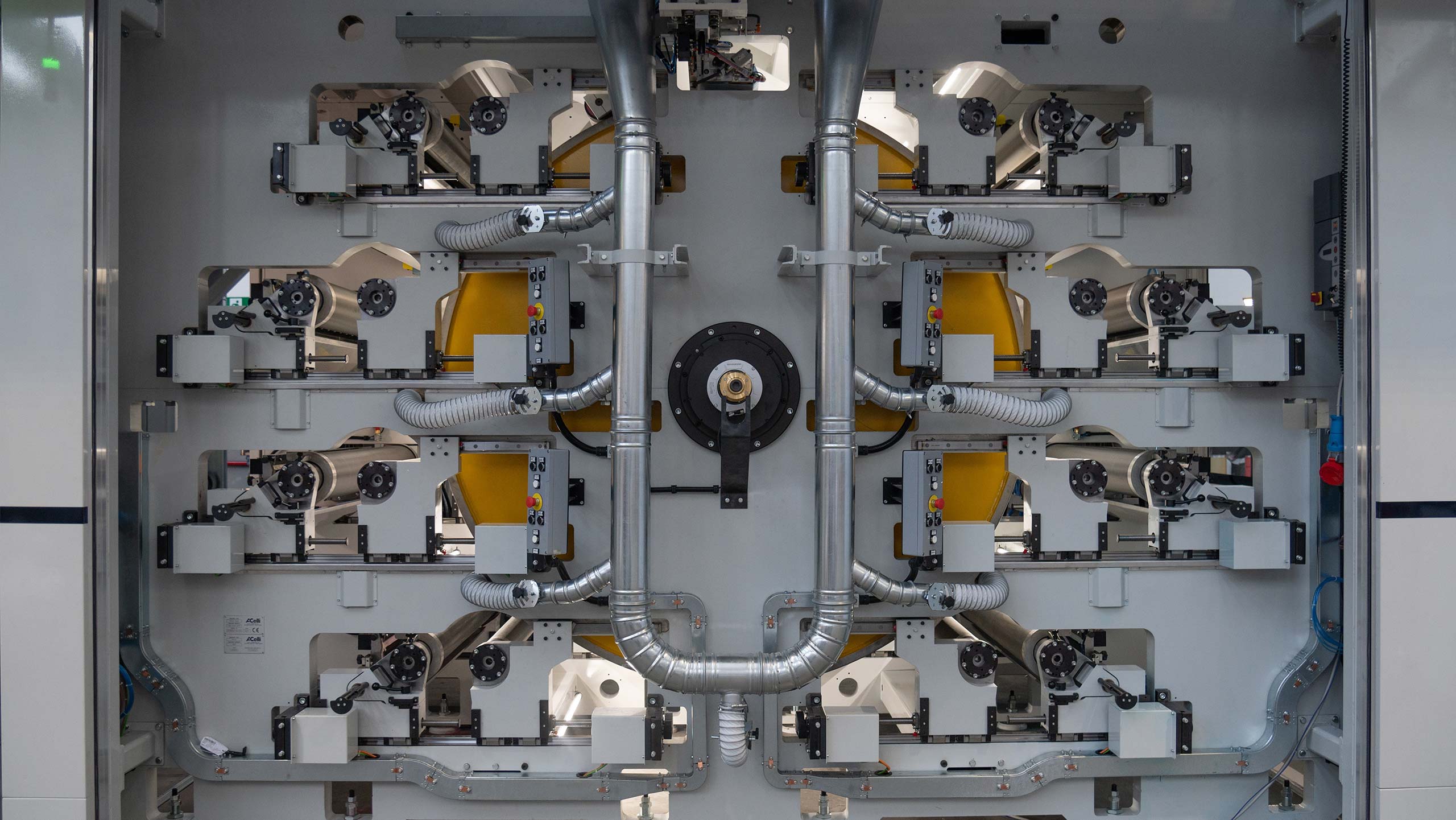

A flexo printing machine is designed to be highly versatile, accommodating different ink types and various printing surfaces. Its core components include the plate cylinder that holds the relief plate, the anilox roll for ink transfer, and the impression cylinder that ensures contact between the substrate and the plate.

The flexo printing process involves a few key steps. The ink is transferred from the ink reservoir to the anilox roll, which then applies a precise amount of ink to the plate. The inked plate comes into contact with the substrate, imprinting the desired design or text.

Flexo printing machines come in different types – stack type, central impression (CI), and inline type. Stack type is suitable for simple designs and smaller runs, while CI and inline types are designed for high-quality, high-volume printing.

The flexo printing machine finds its application in diverse sectors due to its ability to print on both absorbent and non-absorbent materials. This includes food packaging, labels, envelopes, newspapers, and even wallpaper.

Flexo printing offers several advantages. It supports high-speed printing, which leads to greater productivity. Its compatibility with various inks and substrates makes it versatile, and the use of durable plates ensures longer runs without the need for frequent replacements.

When selecting a flexo printing machine, consider factors such as the machine’s speed, print width, ease of operation, maintenance, and of course, the cost. Look for a machine that suits your specific needs, whether you are focusing on small-batch specialty items or large-scale production.

The flexo printing machine is a vital cog in the wheel of the printing industry, delivering high-quality prints across an array of substrates. Its versatility and efficiency make it a preferred choice for businesses seeking to combine speed, quality, and flexibility in their printing processes.

Keywords: Flexo Printing Machine, Flexography, Direct Rotary Printing, Printing Industry, Plate Cylinder, Anilox Roll, Stack Type, Central Impression, Inline Type, High-Speed Printing.